Nanostructured cellulose merits special attention. This material consists of cellulose fibrils or crystallites measuring at least one dimension on the nanoscale. It has the properties of cellulose combined with nanostructured materials' special properties, such as a high specific surface area and distinctive structural features. Although, depending on the processing method used to produce the nanomaterial, nanocellulose properties such as fibre size and surface charge can vary greatly.

In the last decade, nanocellulose research has made tremendous progress, but its application to biomedicine still requires further exploration, especially in the interplay with biological systems. It is therefore necessary to facilitate the development of nanocellulose materials for biological purposes and applications.

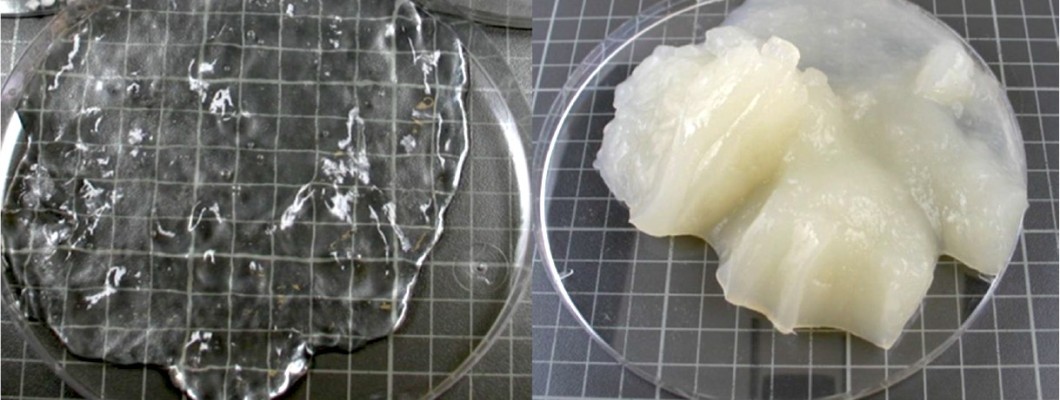

Differences between cellulose and nanocellulose.

Plant

fibres are natural sources of cellulose. In nature, these biocomposites

occur in complex combinations. The elementary plant fibre is a single

cell, usually between 1 and 50 µm long and about 10-50 µm in diameter. A

single fibre looks like a microscopic hollow tube in which a wall of

cells surrounds the central lumen. The cell wall of the fibre consists

of an outer primary P-wall and an inner secondary S-wall. The thin

P-wall (~ 100-200 nm thick) contains a loose network of microfibrils.

The S-wall is 3-6 µm thick and consists of three layers: S1, S2, and S3.

The S1 and S3 layers are nanoscales, and the S2 layer has a thickness

of approximately 2-5 μm. The dominant layer S2 consists of a series of

spirally wound cellulose microfibrils (CMF), which are oriented at an

acute angle to the fibre axis.

CMF

is a cell wall containing an amorphous matrix that consists of lignin,

hemicelluloses, proteins and extractive organic substances. The

CMF and hemicelluloses are bound to each other by hydrogen bonds. On

the other hand, hemicelluloses are more tightly bound to each other by

lignin through single-valent bonds, that is, the hemicellulose component

is the stabilizer between cellulose and lignin. A CMF with a diameter

of 10-30 nm consisting of 30-100 cellulose can lead to an increase in

molecular length.

The

structure and chemical composition of plant fibres differ from one

another and depend on species, age, growth, and climate. This leads to

considerable variation in fibre characteristics and leads to

difficulties in establishing a quality standard. Variability in the

structure and composition of plant fibres contributes to the variability

in plant fibre structure and composition contributes to the mechanical

properties and strength of cellulose.

Contrarily,

nanocellulose is a cellulose fibre that can be extracted. Nanocellulose

fibre size, which is typically less than 100 nm in diameter and

micro-nanocellulose is a biodegradable nanofiber with a low density

(approximately 1.6 g/cm3) and good strength. It has a rigidity of up to

220 GPa, which is considerably high. Nanocellulose also possesses a high

tensile strength (up to 10 GPa), which is greater than cast iron, and a

strength-to-mass ratio eight times greater than stainless

steel. Nanocellulose also has transparent and reactive surface hydroxyl

groups that are functionalized with various surface characteristics.

Nanocellulose

can be divided into three main types: nanocrystalline nano fibrillated,

bacterial, and nanocrystalloid fibrous cellulose. Due to variations in

sources and extraction processes, all forms differ in morphology,

particle size, crystallinity, and certain characteristics.

- Nanocrystalline cellulose - known as cellulose nanocrystals or cellulose nanowhiskers, is a high-strength nanocellulose that is usually extracted from the cellulose fibril by acid hydrolysis. It has a short rod-shaped, or whisker shape, with 2-20 nm in diameter and 100-500 nm in length. In addition, it contains 100% of the chemical composition of cellulose mainly in crystalline areas (high crystallinity of about 54 88%). The crystalline components are retained while the amorphous parts are hydrolyzed and eliminated by acid.

- Nanofibrillated cellulose - known as cellulose microfibrils, micro fibrillated cellulose, cellulose nanofibrils, cellulose nanofibrils, or nanofibrillar cellulose, is a long, flexible, and tangled nanocellulose that can be extracted from cellulose fibrils by mechanical methods. It has long fibrillar shapes from 1-100 nm to 500-2000 nm in diameter. In addition, it contains 100% cellulose in the chemical composition of the crystalline and amorphous regions. Compared to nanocrystalline cellulose, nanofibrillated cellulose has a longer length with a high length to diameter ratio, a high specific surface area, and a high level of hydroxyl groups, which easily enter into surface modification.

- Antimicrobial materials. Interest in using nanocellulose to treat or prevent bacterial infections is based on the fact that it can provide a porous network useful for potential antibiotic transport and can also act as a physical barrier. Since nanocellulose itself has no antimicrobial properties, it is necessary to introduce antimicrobial agents (e.g., silver nanoparticles, lysozyme). Another approach is to chemically modify the nanocellulose material to obtain the desired antimicrobial effect. Some examples of investigated nanocellulose-based materials with antimicrobial activity include: cellulose acetate-based nanofibers containing the antimicrobial agent N-gallamine, aminoalkyl grafted BC films, nanohybrid materials with NCC containing dendritic nanostructured silver, and amino-modified NFC. The study of nanocellulose biocompatibility becomes obligatory if the use of nanocellulose for medical purposes is to be studied.

Nanocellulose in biomedicine

In addition to all of this, nanocellulose is biodegradable, easily accessible, and inexpensive. The great need for biodegradable and sustainable natural resources has prompted study into nanocellulose manufacturing and usage methods. Nanocellulose has been made in a variety of forms researchers use a variety of precursors and techniques (chemical and mechanical). This nanocellulose with improved properties has a wide range of biomedical uses. As polymer nanocomposites, nanocellulose has also been employed. Researchers have high expectations for nanocellulose, which, due to its unique characteristics, hold the potential for the development of bio-nanocomposite materials. For example, nanocellulose may be used as a deformable material, which has such properties as plastic so that it can replace plastic bottles and containers, and hence, it would be a good solution to soil pollution.

1 Comment(s)

Buy Ozempic Without Prescription. Ozempic is a medication approved for the management of type 2 diabetes. Its sometimes used off-label to support weight loss. The only way to get it is through a prescription from a licensed healthcare professional. The best way to get Ozempic is through an in-person consultation with your trusted healthcare professional. If you have diabetes, your doctor may prescribe Ozempic to help manage your blood sugar levels. If you do not have diabetes but are interested in taking Ozempic for weight loss, you may be able to get an off-label prescription for Ozempic from a healthcare professional, if they determine its safe and appropriate for your health needs. The medicine Ozempic is preferably prescribed to patients suffering from type 2 diabetes. The medicine Ozempic contains the very well-known active ingredient semaglutide. This active ingredient is best known because of its very quick action. The active ingredient it contains also inhibits appetite and regulates insulin secretion. In addition, taking the drug Ozempic slows down gastric emptying. The medicine Ozempic requires a prescription and can therefore only be purchased at the pharmacy together with a suitable prescription.

Leave a Comment